Cutting Tools for Milling Machines are game-changers if you work with metal, wood, or even DIY projects at home. They help you achieve cleaner cuts, smoother finishes, and faster results without the struggle of manual tools. Check out Cutting Tools under for more details on cutting tools

These tools are the secret behind everything from precision metal parts to custom brackets and polished work surfaces. Think of cutting tools for milling machines as the ultimate upgrade for your workshop.

Instead of hacking away with hand tools, you let the milling machine do the hard work while you enjoy professional-level results. By the end of this article, you’ll know exactly which cutting tools for milling machines to use, how they work, and how they can save you time, money, and frustration.

View this The Ultimate Guide to Choosing the Right Cutter: Exploring Cutting Tools for Every Need to equip you on how to choose the right cutter for different operations.

What Are Cutting Tools of Milling Machine?

Cutting tools for milling machines are rotary tools that remove material from a workpiece with extreme precision. Unlike single-point cutting tools, they have multiple cutting edges that do the job faster and leave a cleaner surface.

These tools are used in milling machines for everything from creating slots and grooves to shaping complex contours. Whether you’re resurfacing a metal plate or fabricating a custom piece for your next project, milling cutters make it possible.

Why Cutting Tools of Milling Machine Are Important

The right cutting tools for milling machines can turn a difficult job into a smooth one. Using the wrong tool wastes time, wears out your machine, and produces poor-quality results.

For DIY builders and professionals alike, having the right cutters means you can repair, build, and modify things more efficiently. You get precision that simple hand tools just can’t achieve.

1. End Mill – The All-Rounder

End mills are one of the most versatile cutting tools for milling machines. They can cut in all directions – down, sideways, and even diagonally. This makes them perfect for slotting, contouring, and drilling into materials.

You’ll find end mills in different shapes: square, ball-nose, and corner-radius types. If you want to create grooves for a custom bracket or cut an exact profile into metal, this is the tool to reach for.

2. Face Mill – For Smooth Surfaces

Face mills are designed to make large flat surfaces perfectly smooth. They have multiple cutting edges and are excellent for quickly removing material.

Use face mills when you want to resurface a metal plate, smooth out a wooden tabletop, or get an even finish on a garden workbench frame. A face mill is one of the most powerful cutting tools for milling machines for flat work.

3. Ball Cutter – Ideal for Contours

Ball cutters, or ball nose end mills, are made with a rounded cutting edge. They’re the go-to cutting tools for milling machines when you need to create curved surfaces or detailed 3D shapes.

If you’re fabricating decorative elements, making smooth rounded joints, or working on custom garden art projects, ball cutters give a beautiful finish without sharp edges.

4. Slab Mill – The Heavy-Duty Choice

Slab mills are large and powerful cutting tools for milling machines designed to remove big chunks of material quickly. They have multiple cutting teeth that work together for maximum efficiency.

Use slab mills for heavy-duty tasks, like shaping thick metal bars or preparing large plates for welding. They save time when you need to process a lot of material.

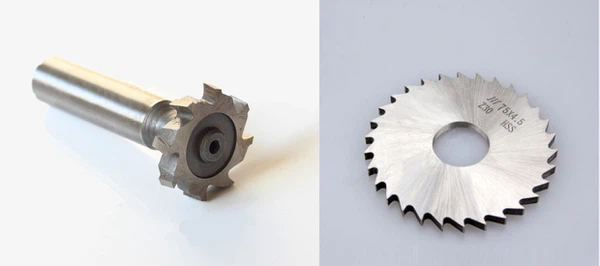

5. Side and Face Cutter – Great for Slots

Side and face cutters have teeth on both the circumference and the sides. This unique design makes them excellent for cutting deep, accurate slots.

If you need to make grooves for sliding brackets or adjustable joints, this is one of the most precise cutting tools for milling machines to use. It ensures clean, straight cuts every time.

6. T-Slot Cutter – Perfect for Adjustable Joints

T-slot cutters are built for one purpose – cutting T-shaped slots. These slots are used for holding workpieces on a milling table or creating adjustable joints in custom frames.

With a T-slot cutter, you can make professional-looking slots for adjustable garden frames, workshop jigs, or any project that needs movable parts.

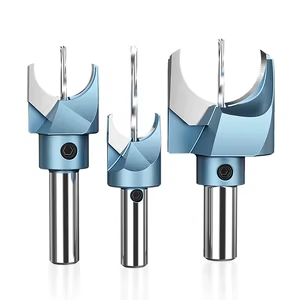

7. Hollow Mill – For Cylindrical Work

Hollow mills are ring-shaped cutters with cutting edges on the inside. They’re perfect for reducing the diameter of cylindrical workpieces.

These cutting tools for milling machines are great for making posts, rods, and shafts fit into precise holes or joints. This comes in handy for greenhouse frames or DIY carts that need exact fittings.

8. Involute Gear Cutter – Making Gears Easy

If you’ve ever seen gear teeth and wondered how they’re made, the answer is involute gear cutters. These tools are designed to cut precise gear profiles.

They’re advanced cutting tools for milling machines and perfect for mechanical projects where gears are required. Think small compost sifters, crank systems, or even custom garden equipment.

9. Fly Cutter – Simple but Effective

Fly cutters are among the simplest but most effective cutting tools for milling machines. They have a single point cutting tool and are excellent for creating very smooth, flat surfaces.

They’re ideal for light milling work where you want a fine finish. Fly cutters are also inexpensive, making them a budget-friendly choice.

Choosing the Right Cutting Tool

Not all cutting tools for milling machines are created equal. The best one for your job depends on the shape you want, the material you’re working on, and the finish you need.

A quick tip: for grooves and slots, go with side or T-slot cutters. For large flat areas, face mills or fly cutters work best. Always match the cutter to the task to get the cleanest result.

Materials of Milling Cutters

Cutting tools for milling machines are usually made of High-Speed Steel (HSS) or Carbide. HSS is great for beginners and light-duty work because it’s affordable and easy to sharpen.

Carbide cutters are more expensive but last much longer and can handle harder materials. If you do frequent milling work, they’re worth the investment.

Safety Tips When Using Cutting Tools of Milling Machine

Safety is just as important as technique. Always wear safety glasses to protect your eyes from chips. Gloves and ear protection are also recommended.

Secure your workpiece tightly and never force the tool. Sharp cutters work best at steady, consistent speeds.

Maintaining Your Cutting Tools

Well-maintained cutting tools for milling machines last longer and perform better. Clean them after every use and store them in a dry place to prevent rust.

Sharpen dull cutters promptly – a sharp tool is safer and produces a cleaner cut. Regular maintenance saves money in the long run.

Choosing the right cutting tools for milling machines can transform your projects from rough and time-consuming to smooth and precise. From end mills to face mills and T-slot cutters, each tool plays a unique role in shaping, slotting, and finishing your workpieces.

Keep them sharp, match them to the right job, and maintain them for longer life. Ready to take your milling skills to the next level? Start exploring these tools today and see how much easier and faster your projects become!